OUR FACILITIES

State-of-the-art facilities equipped with advanced technology ensure high-quality, 100% GMP and GLP compliant, and efficient pharmaceutical manufacturing

Production Room

Our production rooms are designed to meet stringent pharmaceutical standards, ensuring safe, hygienic, and high-quality manufacturing of excipients.

Microlab

The microbiology laboratory is designed to perform accurate microbial testing, supporting the safety and reliability of pharmaceutical products.

Drying and Washing Room

The drying and washing areas are built to support clean operations and precise process control, helping maintain product integrity and uniform quality throughout production.

Storage Room

The storage area is designed to maintain suitable conditions for the safe keeping of pharmaceutical materials, helping preserve their integrity and meet regulatory guidelines.

Retain Sample Room

GMI’s retain sample room is designed for safe and systematic storage of pharmaceutical samples, maintaining controlled conditions to support quality standards and full traceability.

QC Lab

The testing room is set up to conduct precise pharmaceutical testing in a controlled environment, ensuring reliable results and adherence to regulatory standards.

Dispatch Facility

Transportation is carried out with strict handling and monitoring practices to ensure pharmaceutical materials are delivered safely while maintaining their required standards.

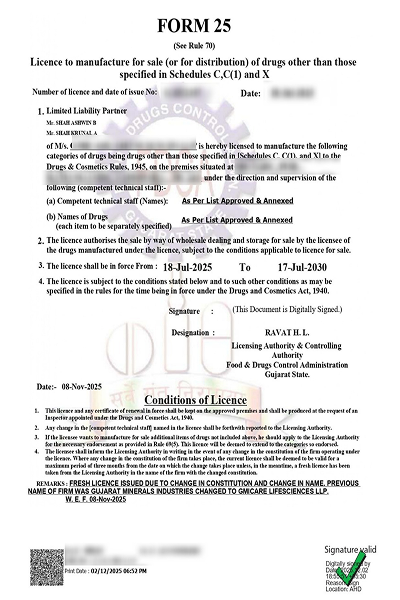

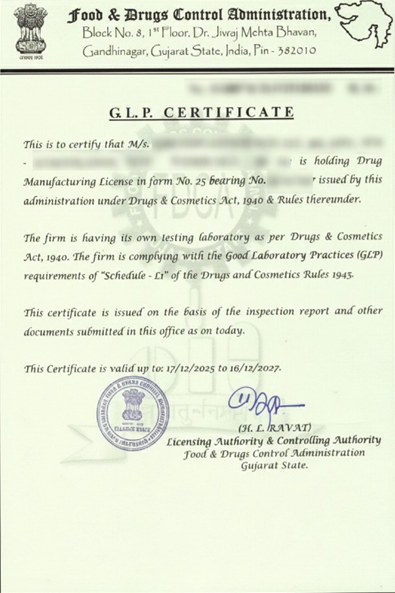

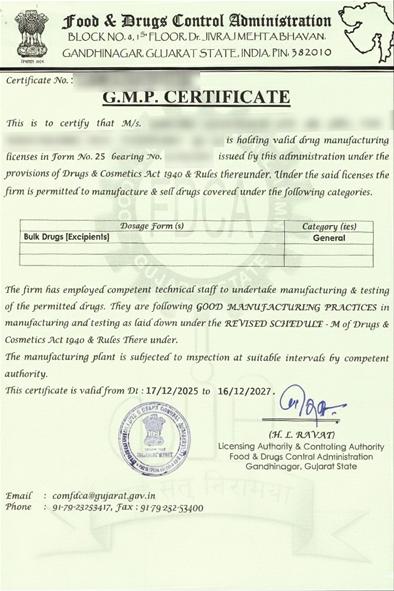

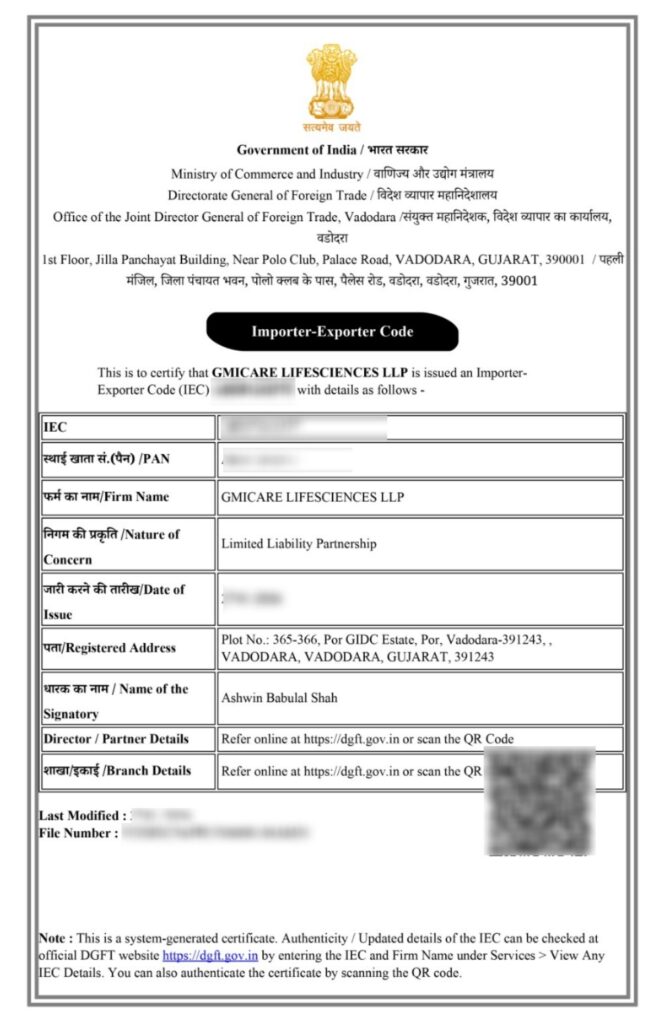

OUR CERTIFICATE

Certified with globally recognized pharmaceutical standards, ensuring quality, safety, and regulatory compliance across all operations.

Drug Manufacturing License

GLP Certified

GMP Certified

Import Export Certificate

FSSAI and ISO Certified